High Tempetraure Polyimide Film Adhesive Tape Label

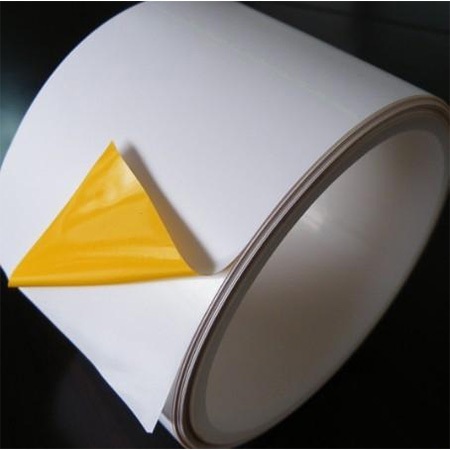

Product Name:Hight Temperature Kapton Tape Label

Product Model:XST-1025W

Backing: Polyimide film

Adhesive:Perpetual Acrylic

Color:Bright White

Polyimide Film thickness:0.025mm

Total Thickness:0.06mm

Width:3mm-500mm

Standard Length:200m/400m

Polyimide Film Tape Label Feature:

1.0-280℃ temperature resistance: put in 280℃ solder 5mintues,no fall off, no out of shape,;resist kinds of chemical erosion, wear and tear;keep the quality stability;meet the international standards in lead-free industrial processes;

2.Apply to the top of SMT process

3.Apply to heat transfer printing technology

4.Comply with ROSH standard

Recomended Color bar:

Recomended to use RICOH-D110A /RICOH-B115C/RICOH-B110CRseries heat transfer ribbon

Product Performance Data(Physical Performance)

Test method: use Zebra type printer or DATA MAX-1-4308 type printer and RICOH-D110A carbon or ROCOH-B110CR carbon at the concentration of 25 print sample labels.Before testing ,the sample is placed on the plate steel stainless and allowed to be placed for 24 hours.

Print effect compare:

1.Compared with Quick Check 500B (aperture:0.005",Wave length:660m),produced by Photographic Sciences company.

2.Read Rate:The scan result by Intermec-®1621canner.

3. saponifier:soak 2minutes in 100ºC ion water

Our Factory Competitive Advantages:

Well Competitive Prices and High Quality Control.

Prompt Delivery.

Earth-friendly Products.

In a Variety of Design.

Small Order Acceptable.

OEM Accepted.

Roll Size: 3″ paper or plastic core;tape width: 2mm -1200mm; standard width: 1200mm, standard length: 50M.

OEM Size: Special length, thickness or combinations can be supplied per customer’s request. Products can be supplied in roll, tape, sheets or shapes per customer’s request. Only you provide the CAD drawing, we can die cut any size for you.

Shelf Life: To obtain best performance, use this product within 12 months from date of delivery and store under normal conditions of 60 ºC to 80ºF (16 ºC to 27ºC) and 40 to 60% R.H. in the original carton.

Main Usage:

Used in printed circuit board,main board,the mobile phone’s high temperature tag;

anti counterfeiting trademakr;hight grade lighting printing trademark, etc...

Technicial Data:

| TEST ITEM | UNITS | TYPICAL VALUES | TEST METHOD | ||

| Polyimide film thickness | um | 25 | ASTM D1000 | ||

| Ink thickness | UM | 15 | |||

| Adhesive thickness | UM | 20 | |||

| Total thickness | um | 60 | ASTM D1000 | ||

| PASTE TO STAINLESS STEEL | 20min | N/100 mm | 42 | ASTM D1000 | |

| 24hour | N/100 mm | 55 | |||

| PASTE TO EPOXIDE PC BOARD | 20min | N/100 mm | 32 | ASTM D1000 | |

| 24hour | N/100 mm | 43 | |||

| Adhesive weight | g/m2 | 25±0.3 | ASTM D1000 | ||

| Initial adhesive | NO/BALL | ≤10 | ASTM D2979 | ||

| 180° Peel adhesion | Kg/25mm | Above 0.6 | ASTM D2979 | ||

| Holding Power | Hr/kg×25mm | Above 48 | ASTM D2979 | ||

| Tensile Strength | kg/25mm | 13 | ASTM D2979 | ||

| Longation at break | % | 55 | ASTM D2979 | ||

| Voltage resistance | KV | >5 | ASTM D1000 | ||

| Temperature resistance | ℃ | –40℃~280℃ | |||

| Insluation resistance | Ω | 1.0×1012 | ASTM D2979 | ||

| Stock enviroment | Keep dry,avoid sunshine ,keep | 10-30℃/60 ﹪ | |||

| humidity | |||||

| Stock period | Year | 1 | |||