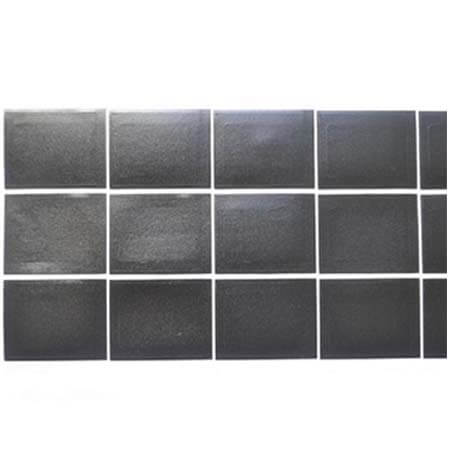

Die Cutting Rogers Poron Foam Sheet

Min Order Quantity: 1000 Square Meters

Supply Ability: 15000 Square Meters

Port: Shenzhen, China

Payment Terms: T/T, L/C, Paypal, Western Union

Delivery Time: About 10-15 days

Die Cutting Rogers Poron Foam Sheet

PORON Microcellular Urethane foams offer a broad range of design solutions for gasketing, sealing, vibration and sound dampening and energy absorption. Low compression set and low outgassing features make these high-performance foams ideal for applications in communications, automotive, electronic, and other industrial devices.

Features:

- Excellent Compression Set Resistance - Durable, long-term performance for gasketing, sealing and cushioning.

- Good Chemical Resistance - Exhibits resistance to corrosion, ozone and UV exposure.

- Energy Absorption - High resiliency, good vibration isolation and impact attenuation.

- Inherently Flame Retardant - Material meets flammability requirements of UL HBF and MVSS 307.

- Low Outgassing - No plasticizers to migrate, non-corrosive to metal, environmentally safe and clean.

Packaging Details:

Export standard packing for Die Cutting Rogers Poron Foam Sheet. (If customers have special requirements, we also can make accordingly.)

Our Factory Competitive Advantages:

- Well Competitive Prices and High Quality Control

- Prompt Delivery

- Earth-friendly Products

- In a Variety of Design

- Small Order Acceptable

- OEM Accepted

Note: All data contained in this document base on china standard test method, they are average values, they should not be used for a specific purpose. All statements, technical information, and recommendations contained are base upon tests that we believe are reliable, but we strongly recommend clients should do their own tests and decide whether the product is fit for a particular purpose or the method of application.

These product properties are suggestive and all products can be customized or converted to fit specific application requirements. Please contact us to discuss your unique application needs.

Widely used in electrical appliances, speakers, electronic toys, computers, lighting, and other products, can let the glue attached with a surface of the finished products have to stop slippery and anti-vibration effect, and communications, electrical products such as small parts of the joint is fixed, protection.

- Sandwich panel: role, no pollution, prevent loose, to prevent the impact noise, prevent sticking.

- LED: prevent light-leaking, absorb shock, high air tightness.

- PCB peripheral: absorbs shock, absorb shock, fill the gaps, the heat insulation effect.

- Keyboard gasket: elasticity, no pollution and good dimensional stability.

- Battery: pollution-free air tightness, to absorb impact sound, progress.

- Floor mat: good grinding, no pollution and good dimensional stability.

- Disk of the tail pads: absorb shock and prevent the impact

- Frictional pads: good grinding, no pollution and good dimensional stability.

- Plate cover soft mat, absorb shock, breaking motor noise, shock, advances the tightness.

- Around the horn: prevent noise, fill the gap.

- LCD: dust, absorb shock, fill the gap, the progress window.

- Surrounding the speaker - to prevent distortion, increase the air tightness, fill the space.

- Transmitter voices around - to prevent distortion, keep the spacing, increase the air tightness.

- Surrounding the vibration motor - absorption of motor and the fuselage vibration, shock, increase the air tightness.

- Shell surrounding, shockproof, keep spacing, increase the air tightness.

- Applicable aspects - need to absorb the impact performance good mobile devices, computers, electronic products, electrical products, electronic medical apparatus and instruments, etc.

| Product Description | Poron Foam Gaskets |

| Material Brand | Rogers, INOAC, NANOCELL, Saint-Gobain, Local material |

| Typical Material P/N | Rogers 4701-30 4701-50 |

| Thickness Range | As per request |

| Industry for use | Automobile accessories |

| Household appliances | |

| Consumer electronics | |

| Processing of | Lamination Cutting Stamping Rotary |

| Die-cutting Capabilities | Cutting Die-cutting Assembly |

| Tighest Tolerance | +/- 0.1mm +/- 0.15mm ISO Tolerance Standard |

| Tape Application | Available, one side or both sides |

| Typical Tape | 3M 467MP, 3M 9448, 3M 9495LE, Nitto, Tesa, Sony |

| Volume | Over 5 million |

| Mold Building: 1-2 Days | |

| Turn Around Time | Sample Lead Time: 3-5 Days |

| Mass Production Lead time: 8-12 Days | |

| First Artical Inspection | |

| In-process Inspection | IPQC |

| Last Artical Inspection |